Following the success of the first phase of our collaboration with CatSci, an award-winning innovation partner for medicines development, we are expanding our AI-driven automation project in medicines manufacturing. This next phase will introduce wearable technology, further optimise productivity, and set new benchmarks for sustainability and operational excellence in pharmaceutical manufacturing.

Building on the previous work, which focused on AI-powered lab data capture and workflow optimisation, this follow-up project extends Lumi’s capabilities to wearable devices, such as smart glasses, enabling hands-free monitoring, real-time process validation, and seamless data integration across manufacturing environments. The goal is to maximise productivity, minimise resource waste, and create a more agile and sustainable pharmaceutical production ecosystem.

Taking AI-driven medicines manufacturing to the next level

In medicines manufacturing, inefficiencies arise from manual sample handling, incomplete data capture, and inconsistencies in process execution. While the initial phase of Lumi’s implementation demonstrated significant improvements in tracking and monitoring critical steps in oligonucleotide production, this new phase aims to push those improvements further. Key advancements include:

- Including wearables to improve data capture in human-led operations and utilise audio in addition to video – Lumi’s integration with LabEye smart glasses will allow scientists, engineers and technicians to automatically record, validate, and contextualise process data without disrupting workflows and worrying about placements of basic cameras.

- Enhanced resource efficiency & sustainability – By reducing waste, minimising redundant steps, and streamlining material usage, Lumi will drive a new level of sustainability in pharmaceutical manufacturing, helping manufacturers align with Net Zero goals.

- Operational excellence & compliance – Lumi’s expanded capabilities will not only improve real-time monitoring but will also support audit-ready documentation, reducing regulatory burden and ensuring high compliance standards.

Demonstrating in CatSci’s oligonucleotide facility

As in the previous phase, our technology will be deployed in CatSci’s oligonucleotide manufacturing facility – a key production process for RNA-based medicines, gene therapies, and next-generation therapeutics. However, this new phase will focus on optimising the entire production pipeline by eliminating inefficiencies at every stage.

With Lumi’s AI-powered insights, CatSci expects to further increase productivity by up to 60% – a significant leap from the previous 40% improvement – by automating workflow transitions, reducing material loss, and improving process traceability.

Another step towards the future of medicines manufacturing

The expansion of this project underscores the industry’s shift towards flexible, agile, and scalable technologies (FASST). Lumi’s AI and computer vision integration with wearables will enhance decision-making at all levels of production, ensuring real-time issue detection, data-driven manufacturing improvements and seamless knowledge transfer.

About Lumi

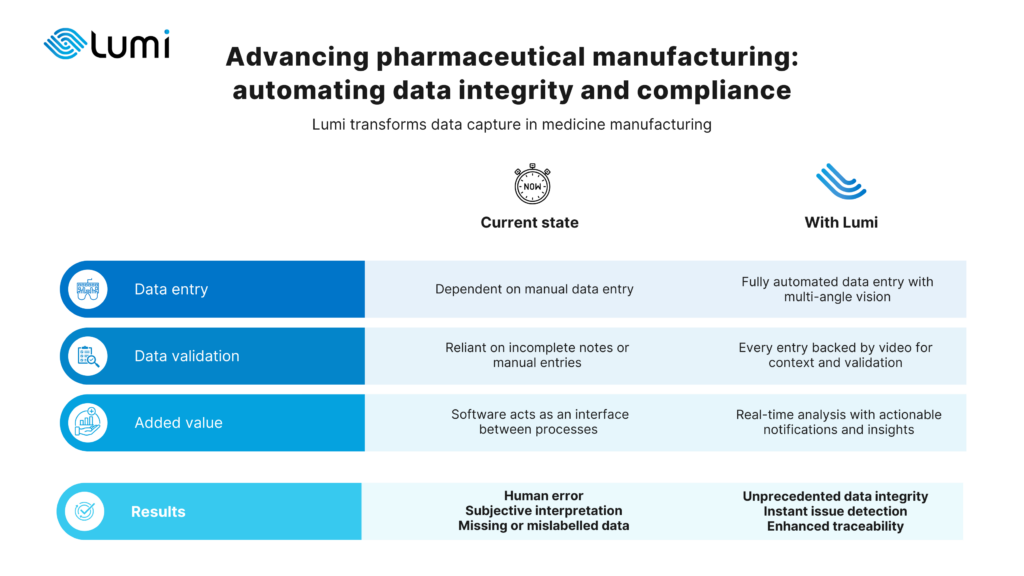

Lumi, developed by Reach Industries, is a visual intelligence platform that transforms pharmaceutical and biotech manufacturing by automating monitoring & data capture in lab and production environments. Lumi enhances productivity, ensures regulatory compliance, and supports the transition to fully digitised and automated workflows.

About CatSci

CatSci is a world-class innovation partner for medicines development, delivering tailored solutions for pharmaceutical manufacturing. With expertise in process research and scale-up, CatSci helps pharmaceutical companies achieve efficient, high-quality production while advancing sustainability and operational excellence.

This project is supported by Innovate UK funding as part of the Sustainable Medicines Manufacturing Innovation: Collaborative R&D competition.